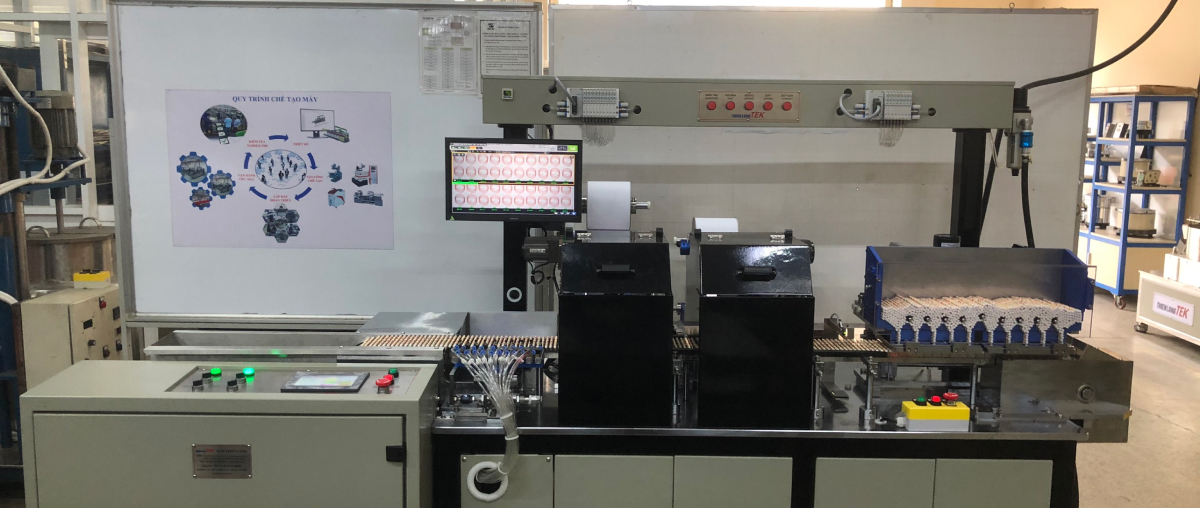

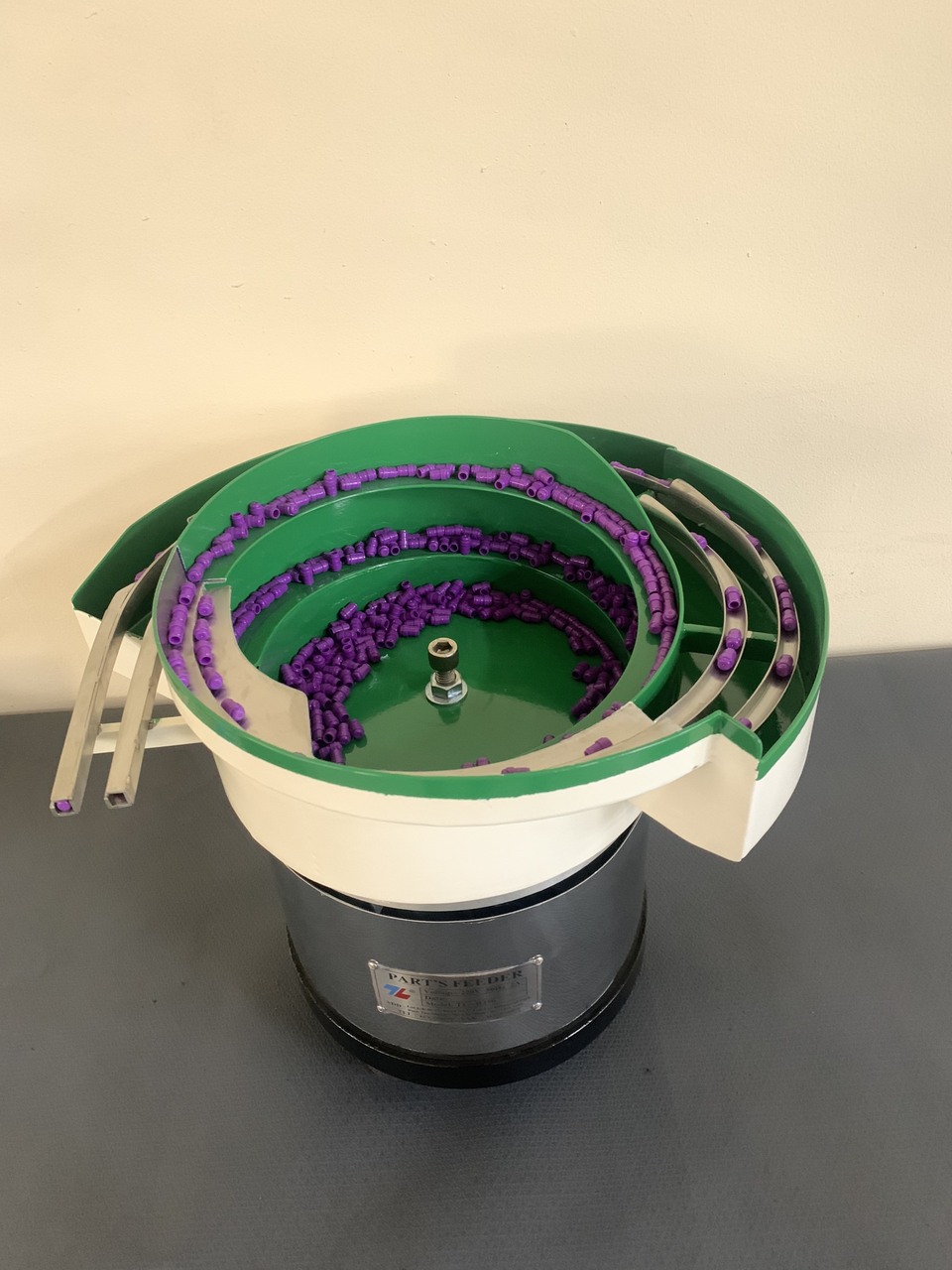

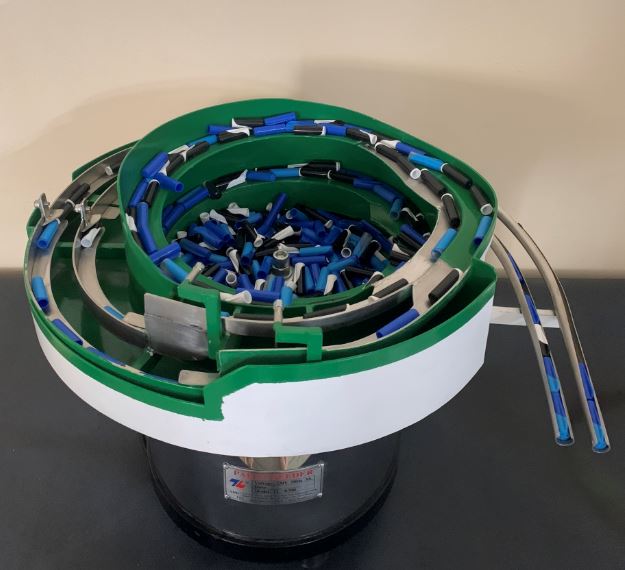

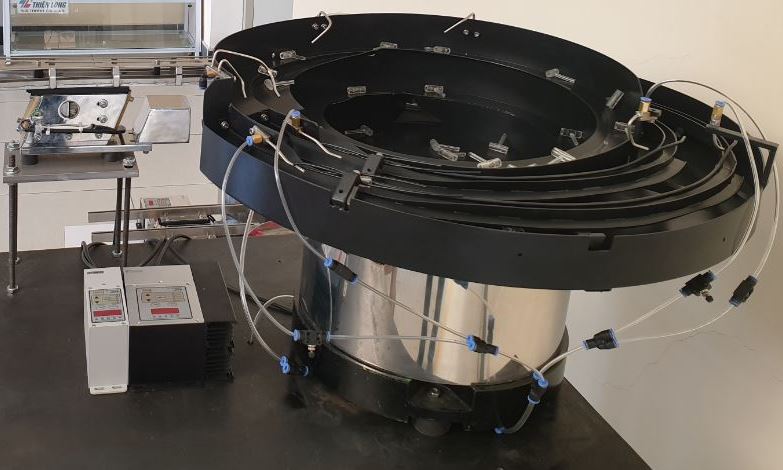

Bowl feeder

Bowl feeder is an important component in the automatic feeding system of manufacturing, assembly and inspection lines. With many years of experience in the field of machine manufacturing and automation line solutions, we provide bowl feeder products according to the requirements of all customers.

Bowl feeder products are designed flexibly according to each type of product and requirements for classification, inspection and measurement, so they are always optimized in terms of structure and operation. Researched, manufactured and assembled entirely at Nam Thien Long factory.

Bowl feeder are used for applications that supply details and products to automatic assembly, inspection, and packaging machines in the electrical and electronic assembly industry, medical, food and consumer products. The machine has the function of classifying, arranging products, counting and checking quickly and accurately.

Advantages of vibrating hopper for workpiece feeding:

Easy to assemble and easy to use

Less vibration, stable.

High reliability, accuracy

Easy to maintain and upgrade.

Disadvantages of Vibrating Hopper:

With a large vibrating hopper size, the noise level will increase due to collision between products. (The solution of making cabinets using sound-absorbing materials can reduce noise by 70%)

Speed depends on product limited to 10-180 products/min.

Many types of products require electrostatic treatment because of the friction in the vibrating hopper.

Depending on the product, the surface of the vibrating hopper is coated with PU paint or hard paint to reduce noise and limit scratches to the product.